3D scanning helps stand out in the highly competitive automotive market. Lower development costs, distinctive design, and stringent quality control are crucial factors in achieving significant strategic goals. 3D Service Company offers 3D scanning services for vehicles and body components such as: Bumpers, Fenders, Doors, Hoods, Roofs, Windows, Wheels.

Our porfolio

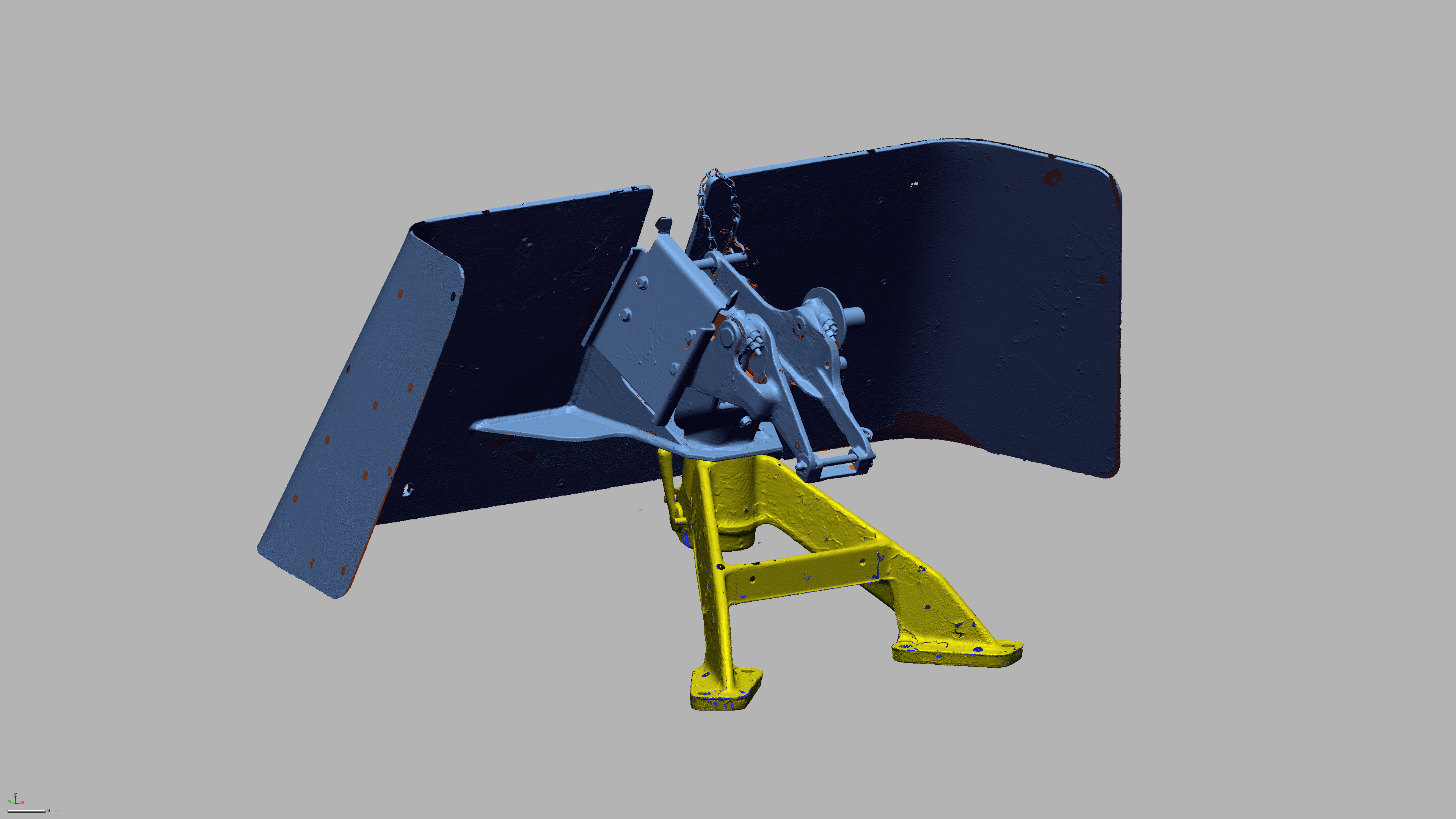

The 3D Service Company offers 3D scanning services for all types of weapons, including rifles, pistols, revolvers, shotguns, and more. We also provide 3D scanning for parts such as stocks, grips, barrels, magazines, bolt carriers, holsters, ammunition belts, projectiles, sights, and others. Additionally, we offer reverse engineering services for these components, including the design or development of elements using information from scanned 3D models.

Our porfolio

We completed a laser 3D scanning service for a Yak-38 aircraft, which is 18 meters long, using a Faro Focus X 330 laser 3D scanner. The scanning process took 4 hours and was conducted outdoors at an aviation museum. Therefore, no challenges are too great for us when it comes to scanning!

Our porfolio

.webp)

.webp)

The price for the service depends on the complexity of the object's geometry and the number of items. Therefore, we first need to understand your needs and the specifics of your project.

Once the goals are set, please upload a photo or request a callback, and we will get in touch with you within a few minutes to provide a cost estimate.

After reviewing the task and processing the information received, we can start working on your project! After scanning, you will receive a 3D model file in STL and OBJ formats. This file represents the point cloud of your object and is fully suitable for rendering and 3D printing.

contact me by:

When is it convenient for you?

The minimum object size we can scan is 10x10 mm, making it suitable for applications in dentistry and jewelry. There is no maximum size limit; even if the object does not fit within the scanner’s field of view, we can scan it in parts and then seamlessly assemble the data.

The ideal surface for 3D scanning is a white matte surface. Generally, all surfaces can be scanned effectively, except for black, glossy, and reflective surfaces. These issues can be easily addressed using a matte spray with talcum powder, which is easily removed after scanning. There are also other techniques, but those are production-specific tricks.

Yes, it's possible to scan with textures. In addition to the 3D model, you will also receive a texture map.